-

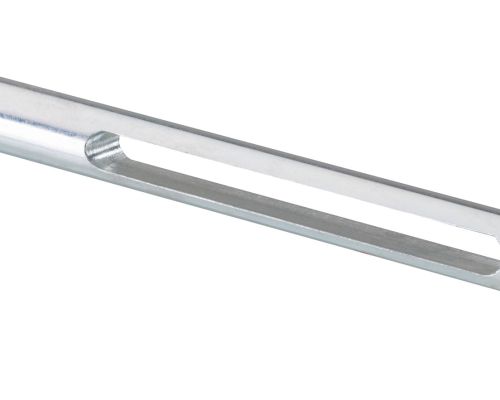

fixed headstockIn our fixed headstock business unit, we can produce parts up to 700 mm working length & 80 mm bar capacity

fixed headstockIn our fixed headstock business unit, we can produce parts up to 700 mm working length & 80 mm bar capacity -

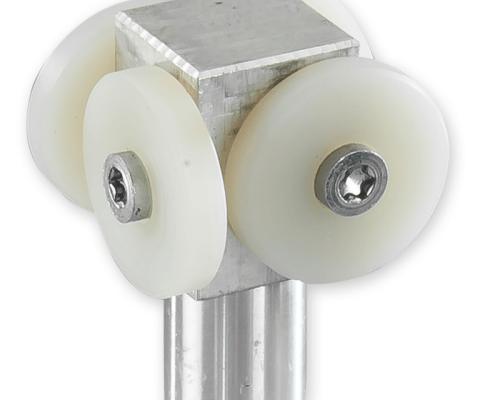

sliding headstockIn our sliding headstock business unit, we can produce parts up to 205 mm working length & 22 mm bar capacity

sliding headstockIn our sliding headstock business unit, we can produce parts up to 205 mm working length & 22 mm bar capacity -

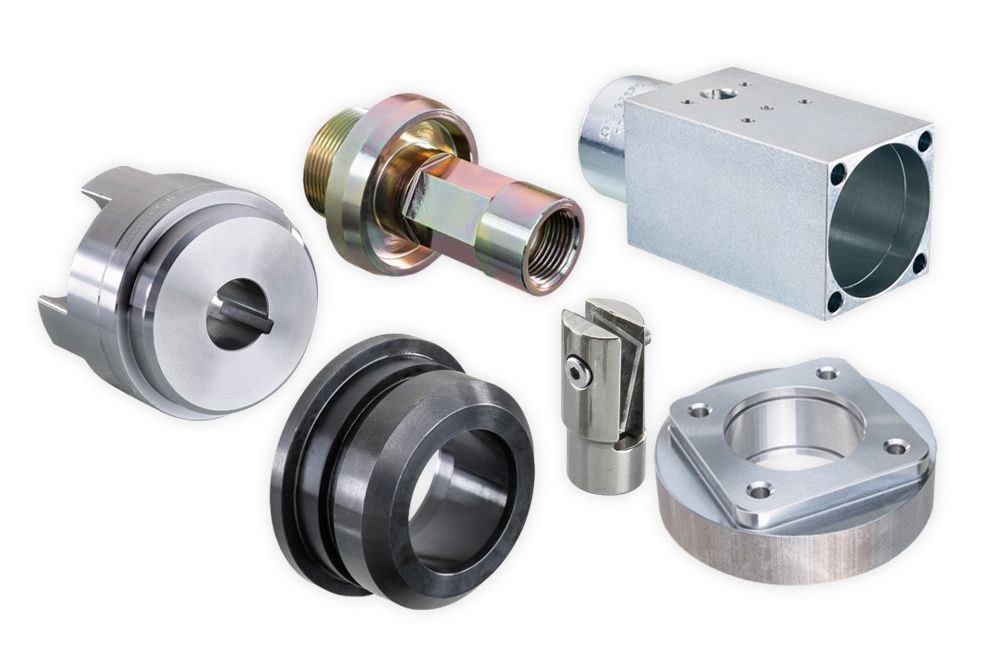

chuck partsIn our chuck parts business unit, we can produce parts up to 80 mm working length & diameter of 205 mm

chuck partsIn our chuck parts business unit, we can produce parts up to 80 mm working length & diameter of 205 mm -

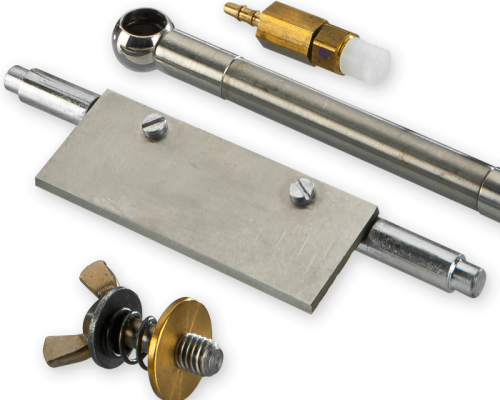

Post-MachiningWe offer a wide range of machining processes for the post-processing of parts or assemblies.

Post-MachiningWe offer a wide range of machining processes for the post-processing of parts or assemblies.

Our Expertise

POST-MACHINING

The following machining processes are available for reworking parts or assemblies:

- mechanical machining processes such as drilling, countersinking, reaming and thread cutting

- rolling of threads and profiles

- pressing, punching and forming work on eccentric and hydraulic presses

- MIG, MAG, TIG and spot welding work

- assembly work

- ultrasonic baths and a modern parts washing machine ensure that parts are free of oil, grease and swarf

- conservation of the cleaned parts

- surface coating such as galvanising, burnishing or colouring in cooperation

- heat treatment in cooperation